Sustainable Barrier Coating

Combining INVO® Coater & INVO® Tip with a light touch of drying creates excellent barriers

The Paper and Board industries are seeking a working, effective and sustainable barrier technology with reasonable capital and running costs.

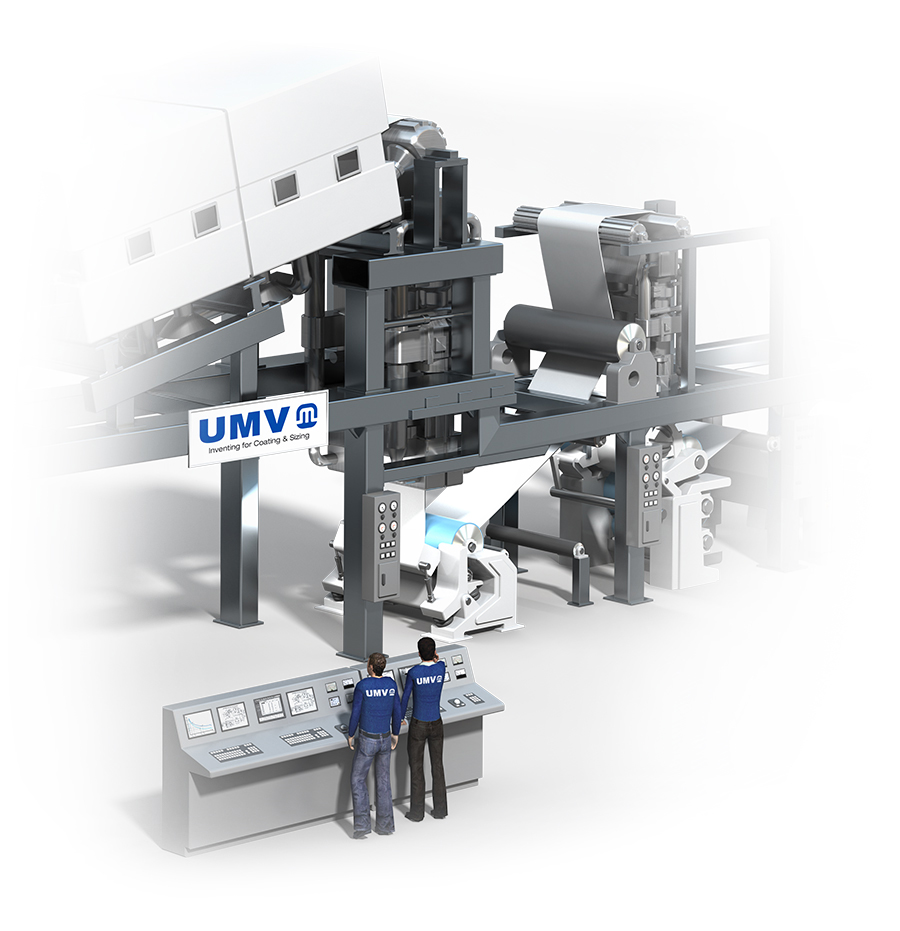

UMV has another approach to this: Multiple Barrier Coating with thin layers. After successful trials at the UMV Pilot Plant in Säffle, Sweden, the conclusion is rock solid. The concept is proven and is based on the combination of the zero dwell INVO® Coater and the resilient INVO® Tip metering element.

By using the UMV set-up for sustainable barrier coating, the capital costs can be reduced to a fraction of competing technologies.

The running costs are also favorable as UMV achieves full barrier with only a few gsm of coating media applied.

We allocate major resources to the field of barrier coating. Recent upgrades have ensured that the pilot plant can now also offer the best conditions for barrier applications.

Capital & running cost can be reduced to a fraction of competing technologies

Features

- Two coating stations, each equipped with drying

- Cooling cylinder prior to pope reel

- Web temperature monitoring system

Benefits

- The interaction between different layers can be optimized

- Control of web temperature

- No blocking